Graphene Oxide: A Sustainable Breakthrough in Food Packaging

🌿 Addressing the PFAS Challenge

Per- and polyfluoroalkyl substances (PFAS) have long been used in food packaging for their water- and oil-resistant properties. However, their persistence in the environment and potential health risks have led to increasing regulatory scrutiny and consumer concern. In response, scientists at Northwestern University have pioneered a graphene oxide-based coating that promises to replace PFAS in food packaging, combining safety, sustainability, and performance.

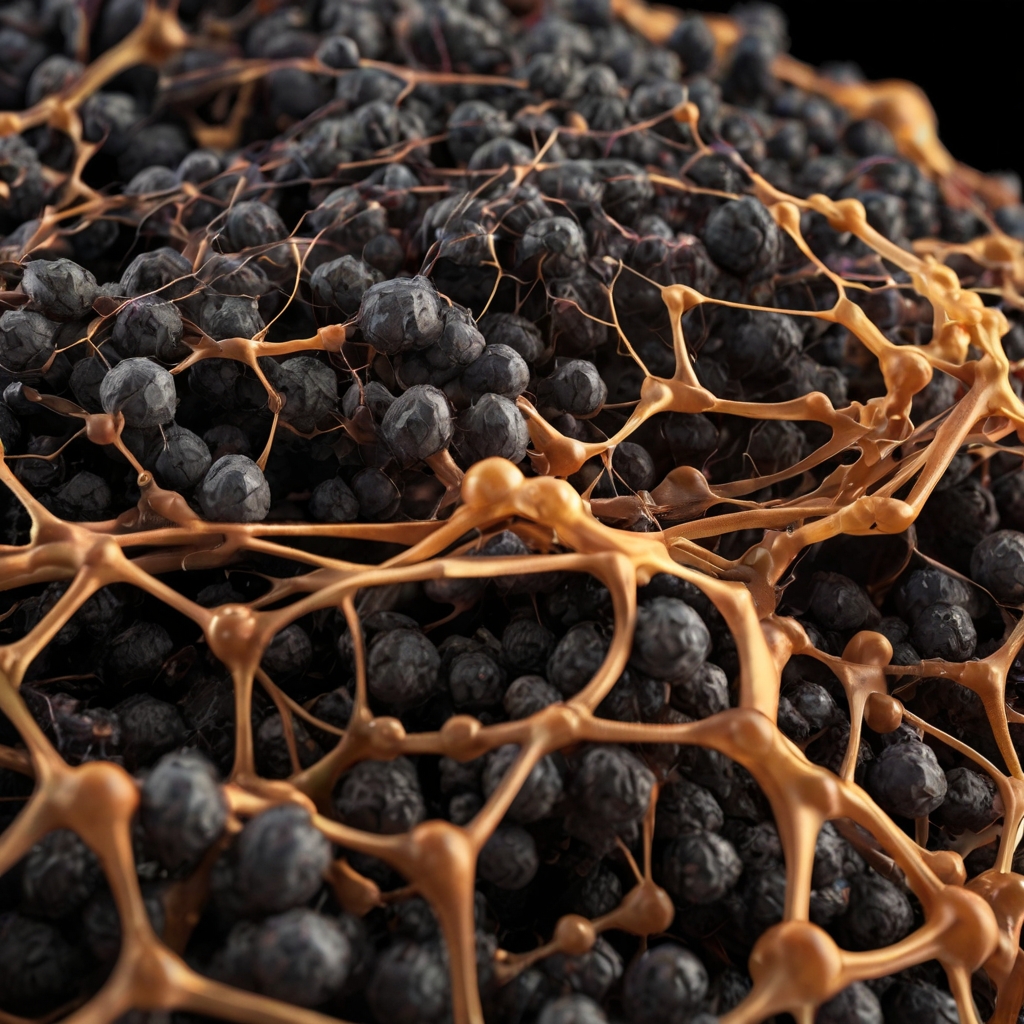

🧪 The Innovation: Graphene Oxide Coating

Graphene oxide, a derivative of graphene composed of single-atom-thick carbon sheets, exhibits exceptional strength and barrier properties. By applying a thin layer of this material to paper-based packaging, researchers have achieved:

-

Water and Oil Resistance: The coating effectively repels liquids, preventing soggy containers and maintaining food integrity.

-

Enhanced Strength: Tests indicate a 30–50% increase in the mechanical strength of treated paper products compared to conventional alternatives.

-

Environmental Safety: Unlike PFAS, graphene oxide is non-toxic, biodegradable, and does not accumulate in the environment or human body.

🏭 Commercialization and Industry Impact

The technology is being brought to market by GO-Eco, a startup incubated at Northwestern's Querrey InQbation Lab and a subsidiary of Chang Robotics. With successful pilot tests and industry-standard evaluations confirming its efficacy, the company is preparing for large-scale production. The coating's compatibility with existing manufacturing processes and its cost-effectiveness make it a promising candidate for widespread adoption in the $60 billion U.S. food packaging industry.

📊 Environmental and Health Benefits

-

Reduced Pollution: By replacing PFAS, the coating mitigates the release of persistent chemicals into ecosystems.

-

Compostability and Recyclability: Treated packaging can be safely composted or recycled, supporting circular economy initiatives.

-

Consumer Safety: The non-toxic nature of graphene oxide ensures that food packaging does not pose health risks associated with chemical leaching.

🔬 Research and Validation

The development involved extensive collaboration between Northwestern's departments of chemistry and mechanical engineering. The coating underwent rigorous testing on various packaging prototypes, including plates, cups, and containers, consistently demonstrating superior performance. Independent assessments at Western Michigan University's Paper Pilot Plant further validated its commercial viability.

🔮 Future Outlook

As regulatory pressures mount against PFAS usage, innovations like the graphene oxide coating offer a timely and effective solution. With plans to seek FDA approval and certifications for recyclability and compostability, GO-Eco is poised to revolutionize the food packaging industry, aligning environmental responsibility with consumer safety.